The garments which come into contact with the body where perspiration is heavy may suffer serious local discoloration. This test is intended to determine the resistance of color of dyed textile to the action of acidic and alkaline perspiration. Before knowing about the Color Fastness to perspiration you must have to know about Color Fastness to Wash and Color Fastness to Rubbing.

The color fastness to perspiration (acid and alkaline) shall be at least level 3-4 (color change and staining). This criterion does not apply to white products, to products that are neither dyed nor printed, to furniture fabrics, curtains or similar textiles intended for interior decoration. A level of 3 is nevertheless allowed when fabrics are both light colored (standard depth < 1/12) and made of silk or of blends with more than 20% silk. This kind of test is specially applied for the sports wear and heavy dresses which is used specially. Normal cloths is also tested by perspiration test.

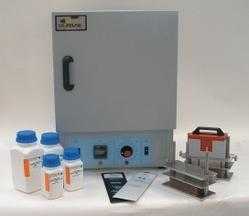

Equipment For Fastness Measurement

Perspiration tester;

Oven, Maintained at 37±2 Degree centigrade;

Multifiber test fabric;

Grey scale;

Color matching chamber;

Acidic and Alkaline solution;

Glass or Acrylic plat;

Weight;

Reagent for Perspiration Test

Solution freshly prepared, containing 0.5g 1-histidine mono-hydrochloride mono-hydrate, 5g sodium chloride, and 2.5g disodium hydrogen ortho phosphate per litre brought to PH 8.0 with 0.1N sodium hydroxide.

Solution freshly prepared, containing 0.5g 1-histidine mono-hydrochloride mono-hydrate, 5g sodium chloride, and 2.2g sodium dihydrogen ortho phosphate per litre brought to PH 5.5 with 0.1N sodium hydroxide.

Two undyed cloths for each specimen each 6×6cm of the same kind of fibre as the sample. Place the specimen between the two pieces of white cloth and sew along one side to form a composite sample.

Working Procedure :

1、Thoroughly wet one composite sample in a solution of PH8.0 at the liquor ratio of 20:1 and allow it to remain in this solution at room temperature for 30min. pour off the solution and place the composite sample between two glasses plates measuring about 7.5×6.5cm under a force of about 4.5kg.

2、Treat the other sample in the same way but with the solution at PH 5.5.

3、Place the apparatus containing the samples in the oven for 4 hour at 37±2C˚

4、Separate the sample from the white cloth and dry them apart in air at the temperature not exceeding 60C˚

5、Assess the change in colour of the specimen and the staining of the white cloth with the greigh scale.