Site: Home > Home > News and events

The Taber Linear Abraser, also known as the Taber Abraser or Taber Wear Tester, is a precision instrument used to evaluate the abrasion resistance and durability of materials. It employs a controlled linear rubbing motion to simulate the wear and tear that materials may experience in real-world applications. Here's how it works:

1. Test Specimens: The material or coating to be tested is prepared in the form of flat panels or samples of specific dimensions. These specimens are typically mounted onto the test apparatus using adhesive or clamping mechanisms.

2. Abrading Wheels: The Taber Linear Abraser consists of a pair of rotating abrasive wheels, also known as abrading wheels or abrasive rollers. These wheels are typically made of a specific material, such as aluminum oxide or silicon carbide, with a predetermined grit size or hardness.

3. Linear Motion: The test specimens are positioned between the two abrading wheels, and a precise linear motion is applied to the wheels. The wheels move back and forth in a straight line over the surface of the specimen, exerting a controlled amount of pressure.

4. Weighted Load: In some cases, a weighted load can be applied to the abrading wheels to increase the contact pressure and simulate more aggressive wear conditions. The applied load can be adjusted to mimic specific real-world scenarios or standard test requirements.

5. Test Parameters: Various test parameters can be adjusted to customize the testing conditions. This includes the number of cycles or strokes, the speed of the linear motion, the applied load, and the type of abrading wheels used. These parameters are typically specified by relevant industry standards or testing protocols.

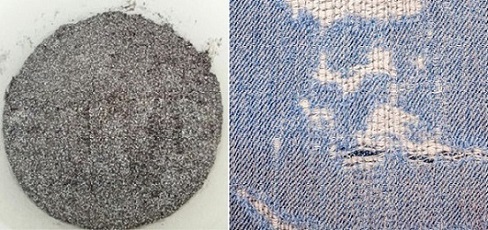

6. Wear Evaluation: As the abrading wheels move back and forth, they gradually abrade the surface of the test specimen. The extent of wear and damage is evaluated and measured after a certain number of cycles or strokes. This evaluation can include measuring the weight loss, examining the appearance changes, and assessing the performance characteristics of the material.

7. Data Analysis: The data obtained from the Taber Linear Abraser testing can be used to compare the performance of different materials, coatings, or surface treatments. It helps in determining the resistance of materials to wear, the durability of protective coatings, and the overall lifespan of the tested samples.

The Taber Linear Abraser is a versatile instrument that can be used to perform a wide range of abrasion tests, including different test methods specified by industry standards such as ASTM, ISO, and DIN. It enables manufacturers to evaluate the performance and quality of their materials, leading to improved product development, quality control, and customer satisfaction.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |