Site: Home > Home > News and events

Here are 10 secrets to help you get the most out of your bending tester and optimize your testing process:

1. Understand the Equipment: Familiarize yourself with the features, functions, and limitations of the bending tester. Read the user manual thoroughly to ensure proper setup and operation.

2. Calibration and Maintenance: Regularly calibrate your bending tester according to the manufacturer's instructions. Perform routine maintenance to keep the equipment in optimal condition, ensuring accurate and reliable test results.

3. Sample Preparation: Ensure your test samples are prepared correctly and consistently. Follow the recommended guidelines for size, shape, and conditioning of the specimens to ensure accurate and meaningful test results.

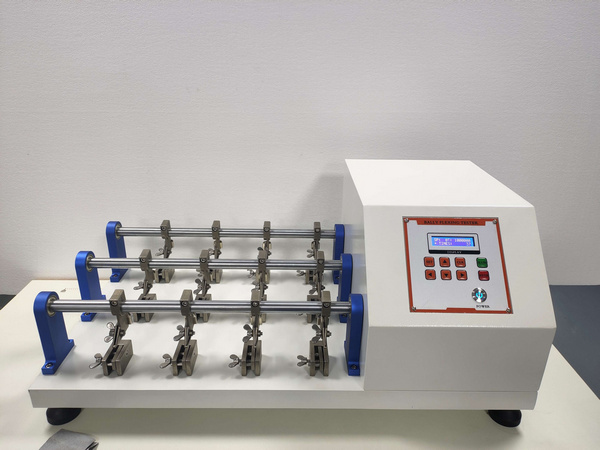

4. Proper Fixture Placement: Position the test samples securely in the bending tester's fixtures or grips to minimize slippage or misalignment during testing. Adjust the fixtures as per the sample requirements to achieve the desired loading conditions.

5. Test Speed and Cycles: Determine the appropriate test speed and number of cycles based on the material properties and intended application. Consider industry standards or specific test requirements when deciding on the test parameters.

6. Data Acquisition and Analysis: Use a data acquisition system or software to capture and analyze test data accurately. Ensure proper sampling rates and synchronization with your bending tester to obtain reliable measurements for further analysis.

7. Safety Considerations: Prioritize safety during testing. Adhere to safety protocols, wear appropriate personal protective equipment, and ensure proper machine guarding to prevent accidents or injuries.

8. Documentation: Maintain detailed records of your testing procedures, including test parameters, sample information, setup details, and test results. This documentation will facilitate traceability and assist in future analysis or comparison.

9. Quality Control: Implement a robust quality control process to monitor the performance of your bending tester. Regularly verify the equipment's accuracy and precision using reference samples or inter-laboratory comparisons.

10. Continuous Improvement: Continuously evaluate and optimize your testing methods. Stay updated with the latest industry standards, techniques, and advancements in bending testing to enhance the accuracy and reliability of your results.

Remember, these secrets are general guidelines, and it is essential to consult your bending tester's user manual and any applicable standards or specifications specific to your testing requirements.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |