Site: Home > Home > News and events

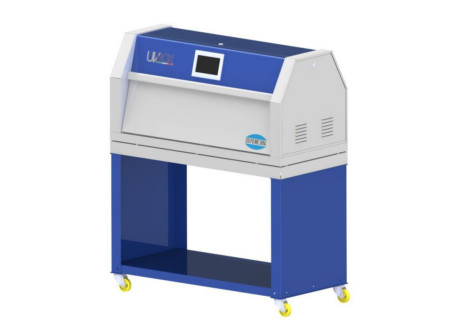

The UV Accelerated Weathering Tester uses a fluorescent UV lamp as the light source to conduct accelerated weathering tests on materials by simulating UV radiation and condensation in natural sunlight to obtain the results of material weathering. It can simulate the environmental conditions of ultraviolet, rain, high temperature, high humidity, condensation, darkness and other environmental conditions in the natural climate. By reproducing these conditions, it is combined into a cycle, and it is automatically executed to complete the cycle number one, UV lamp point not bright. I know that when the UV lamp is in use, sometimes the lamp does not light up, and sometimes it lights up. This is because fluorescent UV Accelerated Weathering Testers generally use electronic ballasts, and the wiring method of electronic ballasts is jack type. Therefore, in some cases, the details of the production process are not handled very well, which leads to the unreliable hidden danger of the connection between the lamp angle line and the electronic ballast. In the future use of course, intermittent disconnection, poor contact and other problems will occur.

1. The UV lamp does not light up.

I know that when the UV lamp is in use, sometimes the lamp does not light up, and sometimes it lights up. This is because fluorescent UV Accelerated Weathering Testers generally use electronic ballasts, and the wiring method of electronic ballasts is jack type. Therefore, in some cases, the details of the production process are not handled very well, which leads to the unreliable hidden danger of the connection between the lamp angle line and the electronic ballast. In the future use of course, intermittent disconnection, poor contact and other problems will occur.

2. Both ends of the UV lamp are black.

This is because the lamp cap of the UV lamp is tungsten, and its melting point is 3410°C. When we light the lamp, the temperature is between 2000 and 3000°C, the filament will not melt, and sublimation will occur, then the sublimated tungsten The vapor encounters the tube wall and condenses into solid tungsten, making it black, and the filament of the UV lamp is at both ends of the tube, so only the two ends turn black. When the UV lamps start to turn black, they need to be replaced. Therefore, in order to better prolong the life of the lamp, please do not start and close the lamp frequently. According to the standard, the lamp should not be turned off for at least 3 hours after the lamp is turned on.

Three, UV sink rust wear.

The Fluorescent UV Accelerated Weathering Tester's water tank is used to hold water for heating, simulating a natural nighttime condensation environment. Because the water tank is made of stainless steel, when using the equipment, if the user does not test by adding deionized water according to the regulations, he adds tap water instead. In this way, after the equipment has been used for about 3 years, the water tank will be corroded by the substances formed by the heating of the water quality and water quality, causing the water tank to rust until the water tank is rusted through.

4. The heating pipe of the water tank is replaced frequently. Because deionized water is not used as required, the heating pipe is soaked in tap water and high-temperature tap water for a long time. We all know that the heating tube is made of stainless steel tube filled with magnesium powder. Therefore, heating work in tap water for a long time will cause the stainless steel on the surface of the heating pipe to be corroded and rust.

Fifth, the instrument failure rate is high.

The instruments of the fluorescent UV Accelerated Weathering Tester are installed on the top of the equipment, so there is a problem: when the equipment is heating (sometimes a test will be done for days or even weeks, the laboratory temperature can reach 60 ℃) In addition, some laboratories do not install air conditioners, and the hot air is rising, so the instrument will suffer from high temperature for a long time. In this high temperature environment, the instrument is prone to failure.

The above is the common fault analysis of UV Accelerated Weathering Tester provided by QISUN, I hope it can help you.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |