Shrinkage is the process in which a fabric becomes smaller than its original size, usually through the process of laundry. Cotton fabric suffers from two main disadvantages of shrinking and creasing during subsequent washing.

Shrinkage is a problem that hampers the dimensional stability of a fabric. A recent survey of manufacturers rated shrinkage as one of the ten leading quality problems. Fabric shrinkage can cause problems in two main areas-

During garment manufacturing;

During subsequent laundering by the ultimate customer.

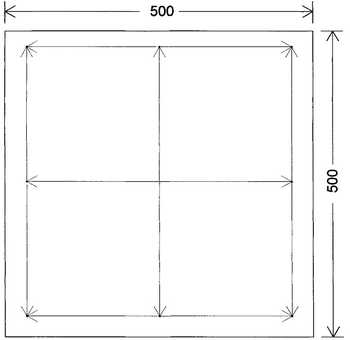

The general procedures for preparing and marking out of samples are given in the British Standard. For critical work the recommended sample size is 500mm X 500mm and for routine work a minimum sample size of 300mm X 300mm is considered as sufficient. The samples are marked with three sets of marks in each direction, a minimum of 350mm apart and at least 50mm from all edges as shown in Figure. In the case of the smaller sample the marks are made 250 mm apart and at a distance of 25 mm from the edge.

Working Procedure:

The sample which is done shrinkage test, spread on table. Then a glass template put on sample fabric which is square size. There are six mark on glass template and distance between two mark is 35 cm. Marking the sample fabric by unchangeable marker. Then sample is sewn by hand sewing machine. Sample is ready for washing. Simple wash the fabric at 60˚c temp for 90 min. after washing the fabric is taken out. Dry the sample as per any of the method. It can either be Line Dry or Flat Dry or Tumble Dry. To find the dimensional change read the Shrinkage/Stretch on 3 points on the Wrap side and 3 points on Weft Side. Get the mean value of wrap-wise and weft wise readings to get the Accurate Shrinkage or Stretch.

Shrinkage is determined as; Shrinkage % = (length of fabric before wash)-(length of fabric after wash))/ (length of fabric after wash) *100

Example,

length of fabric before wash = 35 cm

length of fabric after wash = 33 cm

Now, Shrinkage % = {(35-33)/ 33} * 100

= 6%

Here, Shrinkage is 6%. Normally shrinkage is acceptable less than 5%. But it can be change in case of buyer requirement.