This method describes a procedure for determining the relative flammability of organic films and reinforced composites by measuring the minimum concentration of oxygen in a gaseous mixture of oxygen and nitrogen that will just support combustion. It is based on ASTM Standard D2863-77 but modified to cover thin flexible printed wiring materials.

Procedure

1、Calibrate the flow measuring system at least every six months.

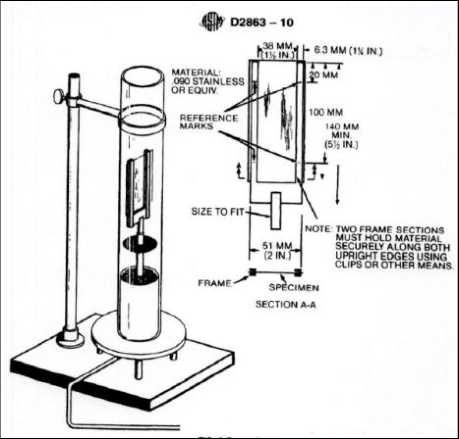

2、Clamp the specimen in the holder vertically in the approximate center of the column with the top of the specimen at least 100 mm below the top of the open column.

3、Select the desired initial concentration of oxygen based on past experience with similar materials. If there is no experience with the material, light a specimen in the air and note the burning. If the specimen burns rapidly, start at a concentration of about 18% but, if the specimen goes out, select a concentration of about 25% or higher, depending on the difficulty of ignition and time of burning.

4、Set the flow valves so that the desired initial concentration of oxygen is flowing through the column. The gas flow rate in the column shall be 4 cm ± 1 cm/sec., as calculated at standard temperature (0°C) and pressure (760 mm Hg) from the total flow of the gas in cm3/sec. divided by the area of the column in cm2.

5、Allow the gas to flow for 60 seconds to purge the system.

6、Ignite the top of the specimen until ignition is apparent or for a maximum of 15 seconds. Remove the ignition flame and start the time.

7、A valid test shall be when a sample burns uniformly for three minutes or a distance of 50 mm.

8、The concentration of oxygen must be raised if the specimen is extinguished before burning three minutes or 50 mm.

9、Adjust the oxygen concentration, insert a new specimen or, if the previous specimen is long enough, turn it end for end or cut off the burned end, then purge and reignite.

10、Continue repeating the test until the limiting concentration of oxygen is determined. This is the lowest oxygen concentration that will meet the conditions of 5.3. At the next

lower oxygen concentration possible with the equipment, the specimen should extinguish.

11、For a material having consistent burning characteristics, the difference in oxygen concentration between burning and extinguishing will be reproducible within 0.1% to 0.3%,depending on the sensitivity of the flow measuring equipment and upon the particular oxygen concentration involved. Some materials, however, exhibit erratic burning characteristics because of inhomogeneity, char formation, dripping, bending,etc., which cause less reproducible results. In such cases, the limiting concentration should be determined by a statistical testing method.

12、Perform the test at least three times by starting at a slightly different flow rate still within the 3 cm/sec. to 5cm/sec. limit.

13、Calculate the oxygen index, n, of the material as follows:n, % = (100 x O2)/(O2 + N2) where O2 is the volumetric flow of oxygen, cm3/sec., at the limiting concentration determined, and N2 is the corresponding volumetric flow rate of nitrogen, cm3/sec.

14、Report The report shall include everything stated in

①、 Description of the material tested including as much as is known about the type, source, manufacturer, manufacturer’s code number, form and principle dimensions, and previous history

②、Test specimen dimensions

③、Average oxygen index value

④、Individual oxygen index values found for each of the tests

⑤、Description of any unusual behavior such as charring, dripping, bending, etc.

Notes:

1、Oxygen Index The minimum concentration of oxygen,expressed as volume percent, in a mixture of oxygen and nitrogen that will only support combustion of a material under the conditions of this method.

2、Principle of Method The minimum concentration of oxygen is in a slowly rising mixture of oxygen and nitrogen that will just support combustion and is measured under equilibrium conditions of candle-like burning. The balance between the heat from the combustion of the specimen and the heat lost to the surroundings establishes the equilibrium. This point is approached from both sides of the critical oxygen concentration in order to establish the oxygen index.