The potential of building materials to contribute to fire growth and spread has lead to extensive regulatory control. Various and numerous small-scale tests are used to simulate and characterize flammability, flame spread and smoke production. Recently Fire Science and Technology Laboratory at CSIRO (FSTL) conducted an extensive research project into the performance in fire of flooring and floor coverings (Blackmore, and Delichatsios 1999). The purpose of this work was to investigate whether few tests (one or two) could be used to provide key flammability properties so that the multiplicity of tests currently available can be validly reduced.

The project focussed on an evaluation of four tests, the Cone Calorimeter, the Flooring Radiant Panel,the LIFT Apparatus and the Early Fire Hazard Test (EFH). The reason behind the test selection was that the first three tests are internationally recognised while the fourth is a valuable, well-documented and validated Australian test. EFH was originally developed to regulate wall lining materials but its use has been extended to regulate almost everything else, including floor coverings. Detailed test measurements in these apparatus included ignition times in the cone and EFH, critical heat flux in the cone, FRP, LIFT and EFH, and rate of heat release and smoke yield in cone and EFH. Comparisons of similar parameters were made to investigate consistency of test results within the present regulatory requirements for floor coverings. In addition, prediction of flooring material behaviour in each of these tests based on results from the rest of the tests was explored.

This work established that the performance measured in and regulated by the Flooring Radiant Panel is complementary to that measured in the Cone. While the Early Fire Hazard Test and Cone provide information to assess the fire performance of materials for upward flame spread, the Flooring Radiant Panel (and LIFT) gives a suitable complementary measure (critical heat flux) of flame spread on horizontal surfaces. While The Flooring Radiant Panel does not currently measure smoke generation nor is it suitable for determining upward flame spread for floor coverings used on stairs or ramps, the Cone Calorimeter can provide the additional data needed for these predictions.

INTRODUCTION:

Recently Fire Science and Technology Laboratory at CSIRO (FSTL) conducted an extensive research project into the performance in fire of flooring and floor coverings (Blackmore and Delichatsios,1999). A previous project had studied wall and ceiling linings (Dowling and Blackmore, 1998). The aim of the project was to recommend tests that provided suitable controls for regulating the use of floor coverings. The resulting recommendation was that to evaluate the hazard presented by floor coverings two tests were needed, and the tests selected were the Cone Calorimeter and the Flooring Radiant Panel (FRP). In addition to regulatory controls, the proposed tests can provide data for fire safety engineering.

The project focussed on an evaluation of four tests, the Cone Calorimeter, the Flooring Radiant Panel,the LIFT Apparatus and the Early Fire Hazard Test (EFH). The reason behind the test selection was that the first three tests are internationally recognised while the fourth is a valuable, well-documented and validated Australian test. EFH was originally developed to regulate wall lining materials but its use has been extended to regulate almost everything else, including floor coverings.

The selected tests measure various aspects of a material’s potential for fire spread, fire growth and smoke generation. The Cone Calorimeter measures time to ignition, heat released as a function of time and smoke generated in terms of optical density. The FRP provides the critical heat flux at which horizontal spread stops. The LIFT Apparatus measures lateral flame spread and provides a critical heat flux that involves the same physics as the critical heat flux measured in the Flooring Radiant Panel. IMO has justifiably chosen to use the LIFT apparatus to regulate carpet applications in ships, acknowledging that the apparatus is not suitable for assessing the performance of melting materials. Because of its physical similarity to FRP, LIFT was not included in the experimental program. EFH results are reported in the form of indices that are related to ignition (Ignitibility Index), upward fire spread (Spread of Flame Index), fire growth (Heat Evolved Index) and smoke production (Smoke Developed Index). As we will discuss later, EFH was developed to assess the

performance of vertical wall linings.

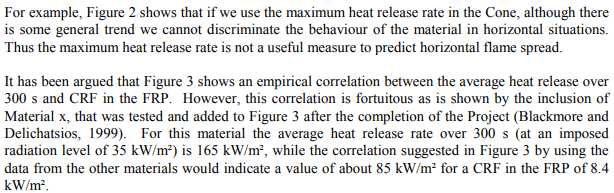

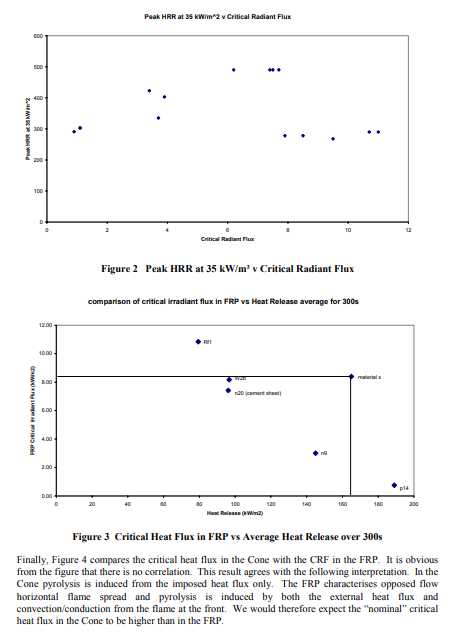

It is difficult to correlate parameters (for example, indices and properties) deduced from

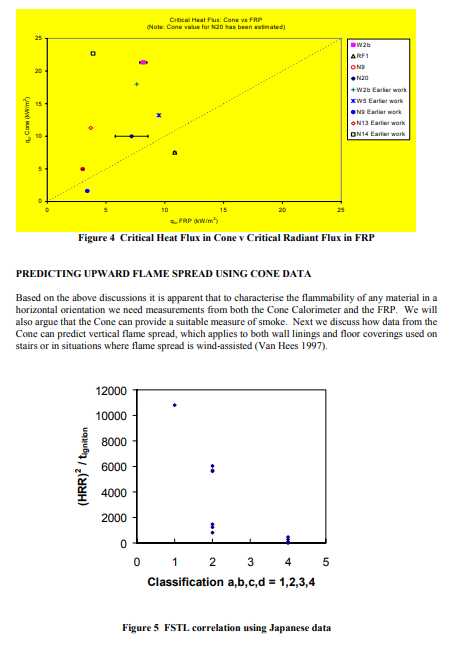

measurements in the selected tests. For example, the critical heat flux in the Cone is calculated from ignition time at different levels of irradiance, and is not assisted by radiation from burning material.The critical heat flux of the FRP (that is defined as the heat flux at which flame spread stops) is primarily affected by the contribution of conductive heat from the flame front and to a lesser degree by the radiation from the flame. Nonetheless, such correlations (or the lack of them) can give us a clear indication of the usefulness of the tests in assessing hazard. Here, we look at a number of comparisons to show why two tests are currently needed to characterise the behaviour of floor coverings, and the reasons for selecting the Cone Calorimeter and the FRP.

In this paper we examine the suitability of tests to measure vertical and horizontal flame spread. We compare various measurements in the Cone Calorimeter with the Critical Heat Flux in the FRP and we look at ways of using data from the Cone Calorimeter to predict upward flame spread. We look at methods of validating flame spread predictions from the FRP in large fire scenarios, and finally we discuss the usefulness of various smoke measurements.

VERTICAL AND HORIZONTAL FLAME SPREAD:

The Early Fire Hazard Test (EFH) is a medium-scale test that is currently called up by the Building Code of Australia (BCA) to control the use of building linings (floors, walls and ceilings). We include a brief description of the test, as it might not be familiar to those outside Australia. A specimen of floor covering 600 x 450 mm is clamped in a vertical holder which faces a gas-fired radiant panel. The specimen holder is moved towards the radiant panel in a series of programmed steps over a period of 20 minutes, or until the specimen ignites, at which time the movement is stopped. Ignition is promoted by a gas pilot flame mounted 15 mm clear of the centre of the exposed face of the specimen, triggering the decomposition products rather than the specimen itself. If ignition occurs the radiation and smoke production of the specimen are monitored for 2 minutes (or more in certain cases) (Dowling and Blackmore, 1998).

EFH is a medium scale test for predicting flame spread on vertical surfaces. Under the current Australian Standard, data obtained can be used to derive indices that are generally suitable for application in deemed-to-satisfy regulations. However, the data is not suitable for use in fire engineering calculations, and the test method itself is not without problems. Its applicability for predicting performance of horizontal surfaces is not appropriate. In addition, certain materials,especially those that melt and drop away from the backing when exposed to heat, give low indices because of the lack of burning material at the point of most intense radiation. This does not reflect their behaviour in a horizontal orientation, where molten material will stay in place until it is burnt.Other materials that have a high critical radiant flux and thus do not ignite easily can produce high flame spread indices in the EFH because these indices are calculated from measurements taken from the time of ignition, regardless of the incident radiant flux at which ignition occurs.

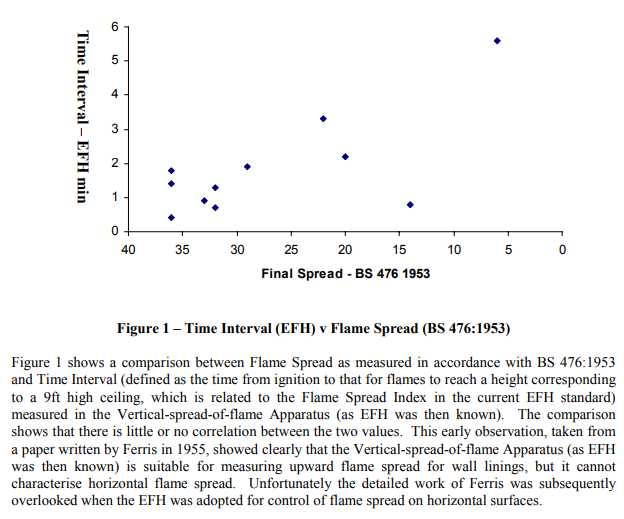

The Early Fire Hazard test was originally developed to overcome difficulties experienced in the use of BS476.7, Surface Spread of Flame Test, for vertical flame spread. BS476.7 measures lateral flame spread on a specimen exposed to a decreasing radiant field. John Ferris of the Commonwealth Experimental Building Station, where the test was developed, was aware that vertical flame spread was different from horizontal flame spread, and that BS 476.7 did not take into account the heat release rate that was necessary to predict vertical spread. He developed the EFH to overcome these difficulties. In the EFH the radiation levels as the panel approaches the burner simulate the radiation levels measured by Ferris in the ASTM or ISO room corner test. EFH became an Australian Standard and measurements in the form of indices for spread of flame and smoke developed were subsequently invoked in regulations to control the use, not only of vertical linings as originally intended but also of horizontal linings.