Site: Home > Home > News and events

The instrument commonly used to measure the coefficient of friction is called a tribometer or friction tester. Tribometers are designed to assess the frictional characteristics between two surfaces by measuring the forces involved during sliding or rolling contact.

There are several types of tribometers available, each suitable for different applications and materials. Some common types of tribometers used to measure the coefficient of friction include:

1. Inclined plane tribometer: This type of tribometer uses an inclined plane and measures the force required to move a sample along the plane. The slope of the plane and the applied force are used to calculate the coefficient of friction.

2. Pin-on-disk tribometer: In this tribometer, a pin or probe is pressed against a rotating flat disk or sample. The frictional forces between the pin and the disk are measured, allowing for the determination of the coefficient of friction.

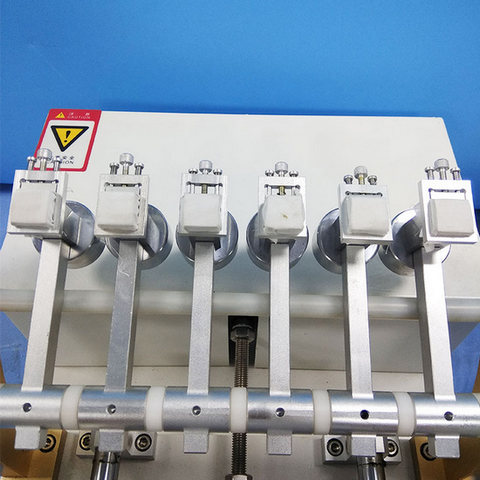

3. Four-ball tribometer: This tribometer uses three stationary balls arranged in a triangle, with a fourth ball pressed against them. The rotational motion of the fourth ball generates friction, and the resulting forces are measured to determine the coefficient of friction.

4. Block-on-ring tribometer: This type of tribometer involves sliding a block against a rotating ring. The frictional forces between the block and the ring are measured, providing data for calculating the coefficient of friction.

Tribometers can be equipped with various sensors and instruments to measure forces, linear or angular displacements, and other parameters required to determine the coefficient of friction accurately. The specific method and procedure for measuring the coefficient of friction may depend on the intended application or standard being followed.

It's important to note that the coefficient of friction can be influenced by various factors, such as surface roughness, lubrication, temperature, and velocity. Therefore, it's crucial to consider these factors during testing and ensure that the tribometer is appropriately calibrated and used in accordance with standardized testing procedures.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |