Site: Home > Home > News and events

Manufacturers typically conduct zipper strength testing in accordance with industry standards such as ASTM D2061 or ISO 13934-2. Here are the general steps involved in zipper strength testing:

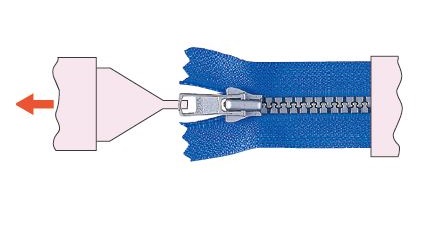

1. Sample preparation: A sample of the zipper to be tested is cut to a specified length and the slider is removed. The two free ends of the zipper tape are then clamped into the jaws of the testing machine.

2. Test conditions: The test is performed under standard conditions of temperature and humidity, which are specified in the relevant industry standard. The temperature is typically 23 ± 2 °C (73 ± 4 °F) and the relative humidity is 50 ± 5%.

3. Initial load: The jaws of the testing machine are separated at a specified speed (usually 102 mm/min or 4 in/min) until the two zipper halves are separated by a specified distance (usually 25 mm or 1 in). A small initial load is then applied to the jaws to ensure that the zipper is securely clamped in place.

4. Test procedure: The jaws of the testing machine are then separated at a constant rate until the zipper fails, which is typically indicated by a sudden drop in force. The maximum force applied to the zipper before failure is recorded, as well as the elongation at failure and the distance between the jaws at failure.

5. Calculation of results: The maximum force applied to the zipper before failure is divided by the width of the zipper tape to obtain the zipper strength in newtons per millimeter (or pounds-force per inch). This value is reported as the zipper's strength or tensile strength.

6. Interpretation of results: The test results are compared to the relevant industry standards to determine whether the zipper meets the required strength and durability specifications.

In addition to these general steps, manufacturers may also conduct other tests to evaluate the performance of zippers under different conditions, such as exposure to water, heat, or chemicals. These tests can provide additional information on the strength and durability of zippers in different environments and help manufacturers to develop more robust products.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |