Site: Home > Home > News and events

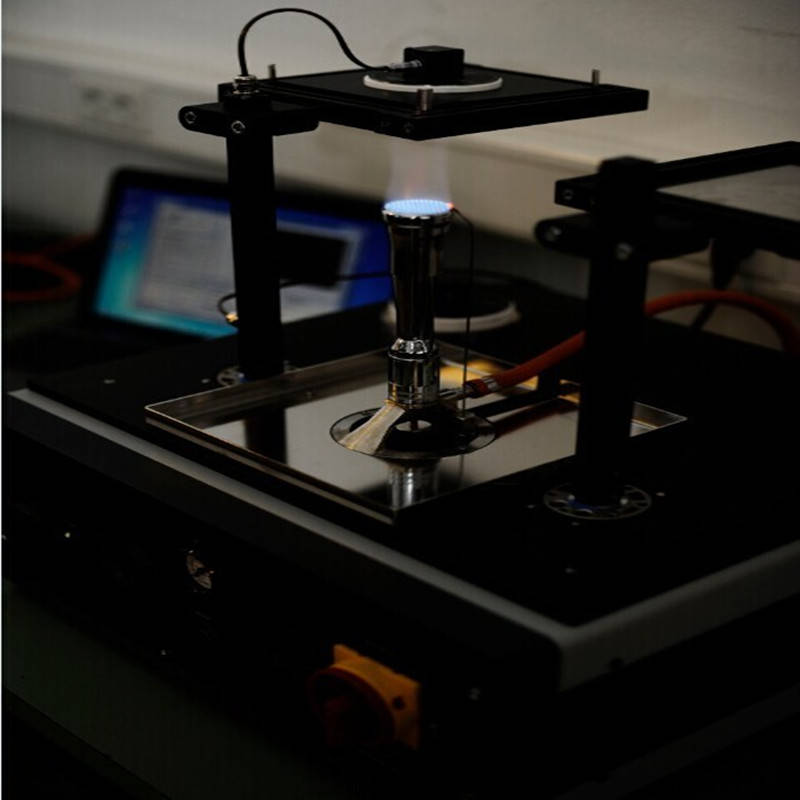

The TPP thermal protection performance tester is a test device developed and produced by QINSUN Instruments for testing the thermal protection performance of protective clothing.

Firefighting clothing is one of the most widely used types of protective clothing to protect the body from heat. The fire scene where the firefighters work is not a dry environment, especially when the firefighters put out the open fire, the human body sweats a lot, the inner layer of clothing will absorb a lot of human sweat, and the firefighting water can also be transferred to the inner layer through the outer surface of the clothing, these moisture vaporised into water vapour under high temperature to the surface of the human skin, which can burn the human skin, so it is of practical significance to study the thermal protection performance of fabrics containing moisture.

Experimental section.

Test materials

The structure of a fire suit is generally divided into four layers, consisting of an outer layer, a waterproof and breathable layer, an insulating layer and a comfort layer. From the various layers suitable for firefighting suits, one was selected as the experimental fabric to compare the changes in thermal protection properties of the different layers after moisture absorption.

Test method

The TPP value reflects the thermal protection capability of the fabric against the combined effect of thermal radiation and thermal convection, the greater the value, the better the thermal protection performance of the thermal protective clothing; conversely, the worse. The test is carried out by placing the specimen horizontally on top of a specific heat source which, at a defined distance, appears in two different forms of heat transfer - thermal convection and thermal radiation. A copper heat flow meter placed on the other side of the specimen measures the temperature at the back of the specimen. The flame is required to be in direct contact with the specimen so that the heat flux reaching the fabric surface reaches 84kw/m2. The heating curve is measured with the copper sheet heat flux meter on the back of the specimen and compared with the Stoll standard curve to obtain the time t required for a second degree burn and multiplied by the exposure heat energy q to obtain the TPP value. The formula is TPP = £2 x q where: q is the prescribed radiant heat flux (84kw/m2); t: is the time required to cause a second degree burn, s. TPP experiments were carried out using a TPP thermal protection performance tester in accordance with NFPAl976 standard.

The specimens were divided into 5 groups, numbered l ~ 5, each group of specimens including A, B, C, D 4 fabrics, each group of each fabric are taken 3 pieces of specimens, each piece of specimens were placed in sealed plastic bags, the first group for the comparison group, without adding water, the second to fifth group of specimens with a spray bottle uniform spray water 5, 10, 15, 20mL. the moisture absorption of the specimens were left in a constant temperature and humidity environment (temperature of 20 ℃ The specimens were left in a constant temperature and humidity environment (temperature of 20℃, relative humidity of 65%) for 24h to allow the specimens to fully absorb the water. The TPP value of the specimens after moisture absorption was measured by the TPP experiment, and the average value of three times was taken for each fabric as the TPP value of the group of specimens.

Experimental results.

① single-layer fabric moisture content on the influence of thermal protection performance, four kinds of fabrics, B fabric moisture content is low, are below 3%, compared with no moisture absorption before basically no change, so B fabric after moisture absorption of secondary burn time and TPP value compared with no moisture absorption before the change is not significant. This is due to the B fabric for polytetrafluoroethylene film, it is a performance * waterproof and moisture permeable fabric, the surface is basically no condensation, so the water content is extremely low. As the comfort layer of flame retardant cotton fabric D absorbs water very well, so the water content is large, followed by the outer layer of fabric A. The moisture absorption in the middle is the insulation layer of insulation felt C. The moisture absorption of all these 3 layers of fabric increases with the increase of water addition, and their secondary burn time and TPP value both increase with the increase of water content. The positive correlation between the moisture content of the single-layer fabric and the secondary burn time and TPP value*, the greater the moisture content, the greater the fabric TPP value, and the corresponding time for the skin to reach the secondary burn will also be extended, so the trend of the moisture content on the TPP value is basically the same as its trend on the secondary burn time.

The linear regression model of TPP value and second-degree burn time was established using SPSS software with TPP value and second-degree burn time as dependent variables and water content as independent variables, respectively.

The one-dimensional linear regression model of TPP value and water content was TPP value = 10.732 + 0.072 × water content, and the one-dimensional linear regression model of secondary burn time and water content was secondary burn time = 5.164 + 0.062 × water content.

Experimental conclusions.

There was a significant correlation between the moisture content of the single-ply fabric and the secondary burn time and TPP values, and a significant linear regression between the secondary burn time, IPP values and moisture content. For every 1% increase in moisture content, the secondary burn time increased by 0.062 s and the TPP value increased by 0.072 kJ/cm2. Both the secondary burn time and the TPP value increased with increasing moisture content. Under combined heat transfer conditions of strong radiation and convection (82.21kw/m2), for single-layer fabrics, moisture contributes to their thermal protection performance, the more water content, the better the thermal protection performance of the single-layer fabric, and under standard conditions, the thermal protection performance of the fabric with water is better than that of the dry state fabric. Under these conditions, the moisture in the fabric will evaporate rapidly, and the radiation convection heat will not be able to transfer to the back of the fabric before the steam takes away some of the heat, and the heat reaching the body is reduced, thus improving the thermal protection performance of the single-layer fabric. The greater the moisture content, the more water evaporates, the more heat is taken away, the speed of heat dissipation is accelerated, and the thermal protection performance of the fabric is further enhanced. This conclusion applies to cases where the moisture content is less than 50%.

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |