Leave Message

Send message or email info@qinsun-lab.com get favorable prices,reply tu you within 24 hours!

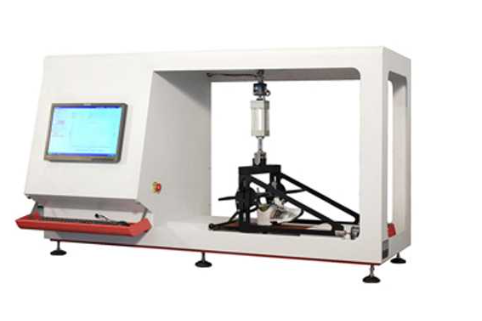

Description:The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the median diameter of the mass produced is 0.6 μ m. Salt aerosol with a concentration of 25mg/m3 and a median mass diameter of 0.3 μ m. An oily aerosol with a concentration of 25mg/m3 is inputted into the self purification detection cabin. The head model is simulated with a sinusoidal curve to simulate respiration. The concentration of salt and oil aerosols before and after the mask is sampled and detected using upstream and downstream photometers, and the filtration efficiency of mask particles is calculated. The mask to be tested can be worn on the national standard head mold to automatically detect respiratory resistance. Applicable to medical device inspection institutes, disease prevention and control centers, hospitals, high-efficiency filter manufacturers, mask R&D and production manufacturers, etc., to test the filtration efficiency of particulate matter such as masks and filter media.

Execution standards:

GB/T6165-2008 Performance Test Methods for High Efficiency Air Filters - Technical Requirements and Test Methods for Efficiency and Resistance of Particle Protection

GB/2626-2006 Respiratory protective equipment - Self suction filtering particulate respirators

GB/T 32610-2016 Technical Requirements for Daily Protective Masks

Technical features:

Integrated design of particulate matter filtration efficiency detection and respiratory resistance detection for masks, with multiple uses for one machine.

The self-cleaning detection cabin is equipped with operating gloves to facilitate the replacement of the mask to be inspected.

Compatibility design for three types of head molds, plug and play for easy replacement.

External salt and oil aerosol generators can be controlled to control the concentration of particulate matter.

Large touch display design, automatically displaying respiratory flow curve and automatically calculating particulate matter filtration efficiency.

The whole process particulate matter leakage prevention design protects the safety of experimental personnel.

Photometer long-life laser light source, high-precision photomultiplier tube detection.

Photometer working time statistics, automatically indicating cleaning time.

Automatically count the usage time of high-efficiency filters and prompt for replacement.

Historical data can be exported through a USB drive or printed through an embedded printer.

Technical indicators:

1. Using a cold aerosol generator to generate continuous and stable aerosol particles, it is convenient to add the solution.

2. Using high-precision PM2.5 sensors to measure aerosol concentration.

3. The whole process particulate matter leakage prevention design protects the safety of experimental personnel.

4. Two sets of aerosol generators: salt particle aerosol generator and oil particle aerosol generator.

5. Equipped with a static charge neutralization device for aerosol particles.

6. Configure temperature and humidity sensors to display real-time environmental temperature and humidity (temperature and humidity requirements: 25 ± 5, 30% RH ± 10% RH).

7. Configure a laser dust particle counter.

8. The protective effect test chamber is designed with a front door opening, good sealing, and equipped with operating gloves for easy replacement of the mask to be inspected.

9. The protective effect test adopts a standard head mold: one standard head mold, which simulates the real situation of a person wearing a protective mask.

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

The particle protection effect tester for masks is equipped with a national standard head mold placed in a 500L self-cleaning detection chamber. The mask to be tested is worn on the head mold, and the

Send message or email info@qinsun-lab.com get favorable prices,reply tu you within 24 hours!

Copyright 2022:Qinsun Instruments Co., Limited

High-end textile tester supplier Email:info@qinsun-lab.com | Textile Testing Equipment pdf | Tel:021-67800179 |